Header

Connecting the real world to the Virtual world with VERICUT

As machining gets more complex and customers expect more for less the need for to simulate, verify and optimize the machining process has never been more compulsory in order to ensure reliability and efficiency, and to maximize productivity.

As machining gets more complex and customers expect more for less the need for to simulate, verify and optimize the machining process has never been more compulsory in order to ensure reliability and efficiency, and to maximize productivity.

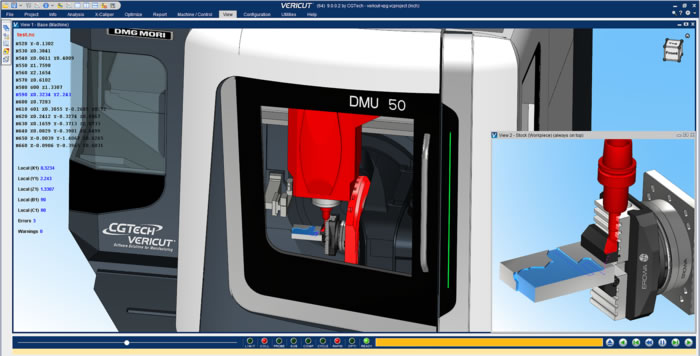

The highest level of NC simulation and verification is achieved using a highly accurate digital twin representation of the CNC machines, which are driven by the same post processed G-code or NC programs that run the machine. A digital twin means to digitally replicate real world component manufacture processes within software.

There are two critical items – are the virtual models correct, matching physical ones, and are the subroutines and parameters from the machine tool being used.

First critical aspect for simulation is making sure that the virtual models of all machine components, attachments, fixtures, clamps, cutting tools etc. match as closely as possible to what is being used on the shop floor in order to create the digital twin. The more accurate the simulation is the more reliable it will be in providing dependable outcomes.

If short cuts are taken, like omitting input data, relying on rough block size or using generic tools, it’s likely that surprises, issues and errors will arise later, which can be inconvenient and expensive on the shopfloor. This is where VERICUTs connectivity comes in.

Secondly is making sure the virtual machine uses actual parameters, subroutines and probing logic taken from the actual machine tool, making the digital twin behave exactly the same as the machine tool and its motions.

It helps having Connections

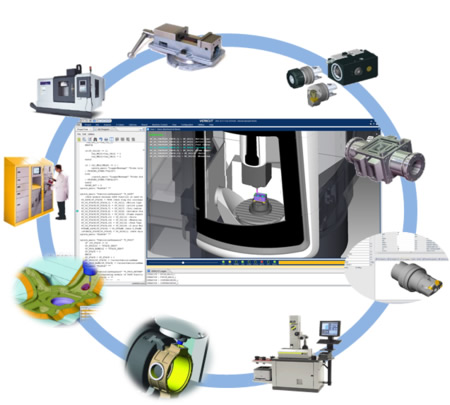

VERICUT can directly connect and communicate with multiple sources of software, including CAD/CAM, tool management systems and data from vendors and the cloud. This gives access to the most current information available and ensures that the virtual machine and simulation is as accurate as possible.

Using direct interfaces with all leading CAM systems VERICUT creates a seamless integration between the CAM system and simulation software, which streamlines data flow, avoids replication, eliminates human error and makes the transfer for multiple setups and operations quick and easy. Different stock models, design or finished parts and fixtures can be selected and imported into VERICUT ready to run a simulation – as simple and easy as that.

Likewise, with connections to various Tool management systems, including the Machining Cloud, Novo and Zoller etc. VERICUT can access a central source for cutting tool information and obtain highly accurate tool models. Other information such as speeds and feeds can be brought into VERICUT from the TDM system and used by programmers as a guideline to ensure that tools are not being over or under utilized or as a starting point for optimizing programs.

Connection goes both ways

Connectivity also goes beyond the information imported into VERICUT and also extends to the resulting simulation data that can be shared with other departments in order to improve efficiency. VERICUT has various tools that streamline communication and connectivity throughout the manufacturing process.

Connectivity also goes beyond the information imported into VERICUT and also extends to the resulting simulation data that can be shared with other departments in order to improve efficiency. VERICUT has various tools that streamline communication and connectivity throughout the manufacturing process.

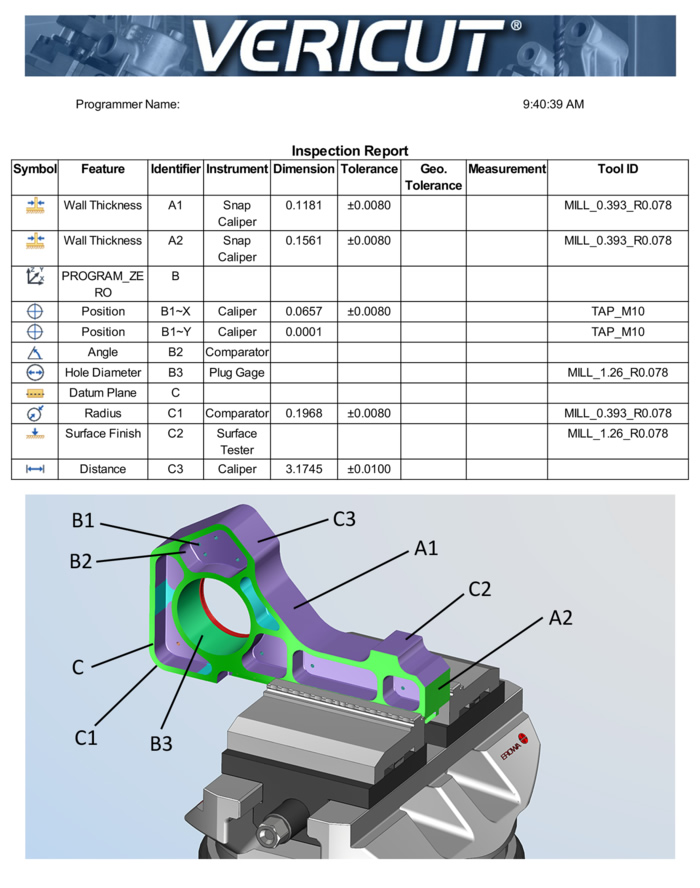

As well as reports that can be configured to run automatically after the simulation, log files, cutting data and images, VERICUT offers a complete Reviewer file. This is a file that can be opened by any Windows PC or tablet and allows users to view the full simulation. It’s a 3D representation of the simulation that can play forward and backward while removing and replacing material. The user can rotate, pan and zoom just like normal VERICUT, and the cut stock can be measured using all the standard X-Caliper tools. Tools such as reviewer and reports allow complete visibility throughout the manufacturing process of how parts should be produced and connects the entire workflow together.

Accurate simulation data means that the planning and scheduling department will have a better indication of cycle times, tool life information will be available for pre-setters, machinists will have confidence that the fixtures and programs are going to run correctly, NC Programmers can be assured that the process is actually producing the part as intended, and process engineers and quality control can easily trace errors or issues in the design or NC program. All this data can be collated before any actual machining is done, without wasting machine time, and can be fed back to high level personnel for operational planning and budgeting.

So when the virtual world matches the real world chances for surprises in the shop are massively reduced, the manufacturing workflow operates more efficiently and maximizes time and therefore cost savings. VERICUT connects the process together and ensures the most accurate and reliable representation of the real world.

So when the virtual world matches the real world chances for surprises in the shop are massively reduced, the manufacturing workflow operates more efficiently and maximizes time and therefore cost savings. VERICUT connects the process together and ensures the most accurate and reliable representation of the real world.

###

Note to Editors

About CGTech

CGTech’s VERICUT® software is the standard for CNC simulation, verification, optimization, analysis, and additive manufacturing. CGTech also offers programming and simulation software for composites automated fiber-placement, tape-laying, and drilling/fastening CNC machines. VERICUT software is used by companies of different sizes in all industries. Established in 1988, and headquartered in Irvine, California; CGTech has offices worldwide. For more information: visit the CGTech website at cgtech.com, call (949) 753-1050, or email info@cgtech.com.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan