Header

OMIC R&D Publishes White Paper on CGTech’s Force Optimization

-

FOR IMMEDIATE RELEASE

Contact: Virginia Steverson

949-753-1050

Virginia.Steverson@CGTech.com

Irvine, California – The Oregon Manufacturing Innovation Center, Research and Development (OMIC R&D) has published a review of CGTech’s VERICUT Force Module. The Project was designed to offer an unbiased review and evaluation of VERICUT Force for OMIC R&D members from an experienced user of the software.

Irvine, California – The Oregon Manufacturing Innovation Center, Research and Development (OMIC R&D) has published a review of CGTech’s VERICUT Force Module. The Project was designed to offer an unbiased review and evaluation of VERICUT Force for OMIC R&D members from an experienced user of the software.

CGTech specializes in numerical control (NC/CNC) simulation, verification, optimization, and analysis software technology for manufacturing. CGTech’s VERICUT software is the industry standard for simulating CNC machining in order to detect errors, potential collisions, or areas of inefficiency. VERICUT + Force provides an integrated simulation-optimization solution that can significantly reduce machining times, and improve cutting tool and machine life.

“Force from CGTech is one of the most exciting new tools for predicative processes control I have utilized,” said Joshua Koch, Operations Lead at Oregon Institute of Technology and author of the white paper. “Having been in the industry for over a decade and programming for half of that, it’s easy to see how the Force workbench is leading the way in predicative and optimization systems for manufacturing. The system changes the fundamental approach to NC program creation, reducing failure potentials while optimizing toolpath. I am excited to show manufacturers the potential for savings that exists in their NC programs.”

OMIC R&D is the fifteenth such research center established with Boeing leadership worldwide, and the first Boeing has sponsored in the United States. Its mission is to bring together manufacturing companies and higher education in an innovation environment where “outside-in” applied research with faculty and university students solves real problems for advanced manufacturers while training the next generation of engineers and technologists.

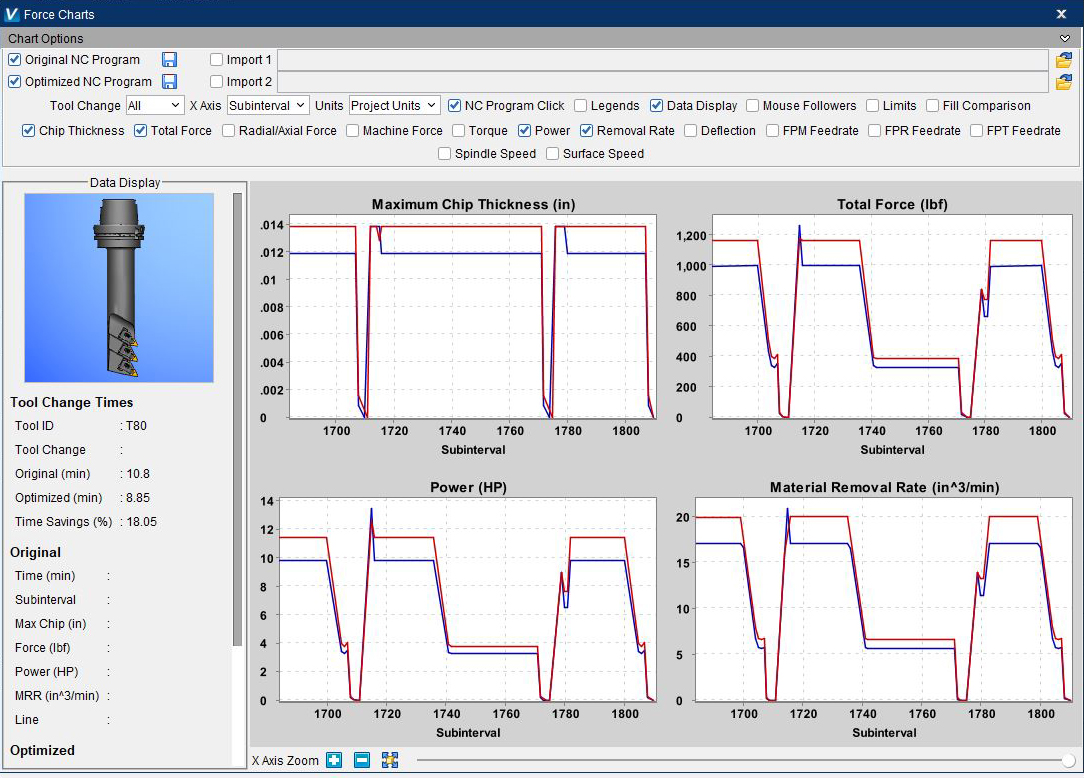

The Project was designed to test how Force could improve productivity and reduce costs for machining parts in Mill-Turn applications. The testing concluded that VERICUT Force can reduce cycle times and avoid premature tool wear/chipping after an NC program has been proven out. Using a previously programmed and already highly optimized Aerospace component, Force optimization demonstrated additional cycle time reduction of 17% over the original program.

“The growth of OMIC R&D to include a great number of industry-leading companies, has provided a unique opportunity to collaborate in a non-competitive environment. The value of this type of collaboration is demonstrated through research projects such as this one, that provide leading edge answers to difficult industrial problems.” – Boeing

“CGTech is proud to be an OMIC R&D partner,” says Jon Prun, CGTech President. “Educating students and manufacturers about the benefits of VERICUT Force is just one of the ways that CGTech is working with the industry to help solve manufacturing challenges, and adapt to rapidly evolving technologies."

CGTech is one of over 30 industry and university members participating with the OMIC R&D Scappoose facility.

To view or download the white paper, Click Here.

About CGTech

CGTech’s VERICUT® software is the standard for CNC simulation, verification, optimization, analysis, and additive manufacturing. CGTech also offers programming and simulation software for composites automated fiber-placement, tape-laying, and drilling/fastening CNC machines. VERICUT software is used by companies of different sizes in all industries. Established in 1988, and headquartered in Irvine, California; CGTech has offices worldwide. For more information: visit the CGTech website at cgtech.com, call (949) 753-1050, or email info@cgtech.com.

About the Oregon Manufacturing Innovation Center

OMIC R&D has built a powerhouse consortium of industry and academic leaders committed to combining their knowledge and experience to advance manufacturing to the next stage. The key to this dynamic effort is invested collaboration. Through collaboration, innovation is born, resulting in applied solutions for manufacturers to make products better, faster, greener and less expensively. OMIC R&D’s capabilities can benefit companies that may not have the time, focus, or bandwidth to address research issues themselves. OMIC R&D is modeled after the Advanced Manufacturing Research Center established with Boeing at Sheffield University in England. AMRC was founded to help manufacturers of any size become more competitive by introducing advanced techniques, technologies, and processes, and to carry out world-leading research into advanced machining, manufacturing, and materials that are of practical use to industry. For more info about OMIC R&D visit www.OMIC.us

# # #

EDITOR’S NOTE: Electronic images attached – Optimized_ID_TIger_Claw.jpg

ECaption: Initial parameters in blue and optimization results in red for ID Tiger Claw

CGTech, VERICUT, and OptiPath are registered trademarks of CGTech.

AUTO-DIFF and X-Caliper are trademarks of CGTech.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan