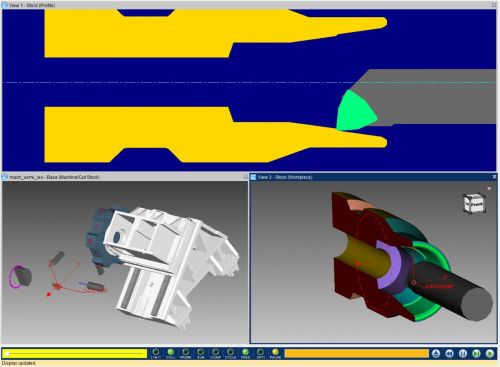

Staying competitive as a job shop often means meeting high standards while minimizing programming, setup, and processing times. VERICUT makes efficient production of high-quality components easier than ever. Cut machining times and eliminate prove outs by simulating your NC program to detect and prevent collisions, gouges, and other issues.

Explore Resources and User Stories

-

MIC Group LLC User Story

When you machine parts of all sizes in materials ranging from nickel and cobalt-based superalloys to titanium and copper, catching mistakes before a workpiece is scrapped or a machine tool crashes is critical.

Learn why MIC Group LLC uses VERICUT to verify toolpaths and protect their array of CNC machine tools.

-

Micro-Mechanics User Story

Keep the potential for crashes low, especially when you're investing in new CNC machines. Read more about how Micro-Mechanics uses VERICUT to protect their machines, review toolpaths, and simulate complex macro-probing routines.

-

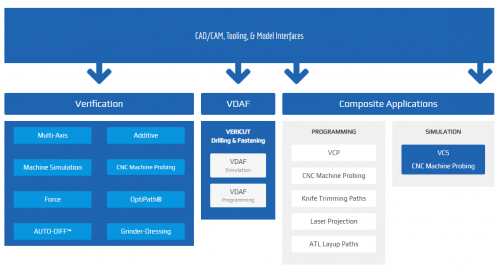

Explore Our Full Product Line

VERICUT offers solutions in machine simulation, verification, optimization, and more. Find the right modules to protect your CNC machines while increasing throughput.

-

VERICUT Force Optimization

VERICUT Force Optimization optimizes new and existing NC programs according to changes in cutting conditions. Protect your CNC machines and extend your tool life; watch the user story from Sandvik Coromant Mebane.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan