John Giraldo (Sr Applications & CAM Engineer at Sandvik Coromant) Identifies Problem Areas in NC Programs with Force Analysis

On a recent customer assignment, a particular part feature was very small and the space to fit a tool was limited. This required the use of small endmills (2-4mm) to machine 50 slots on the part. As John began machining on the part, the endmills started breaking on the initial operations, sometimes before completing just one slot. Using CAM optimization methods and advanced cutting techniques including the use of trochoidal toolpaths, were not helping, and the tools continued to break.

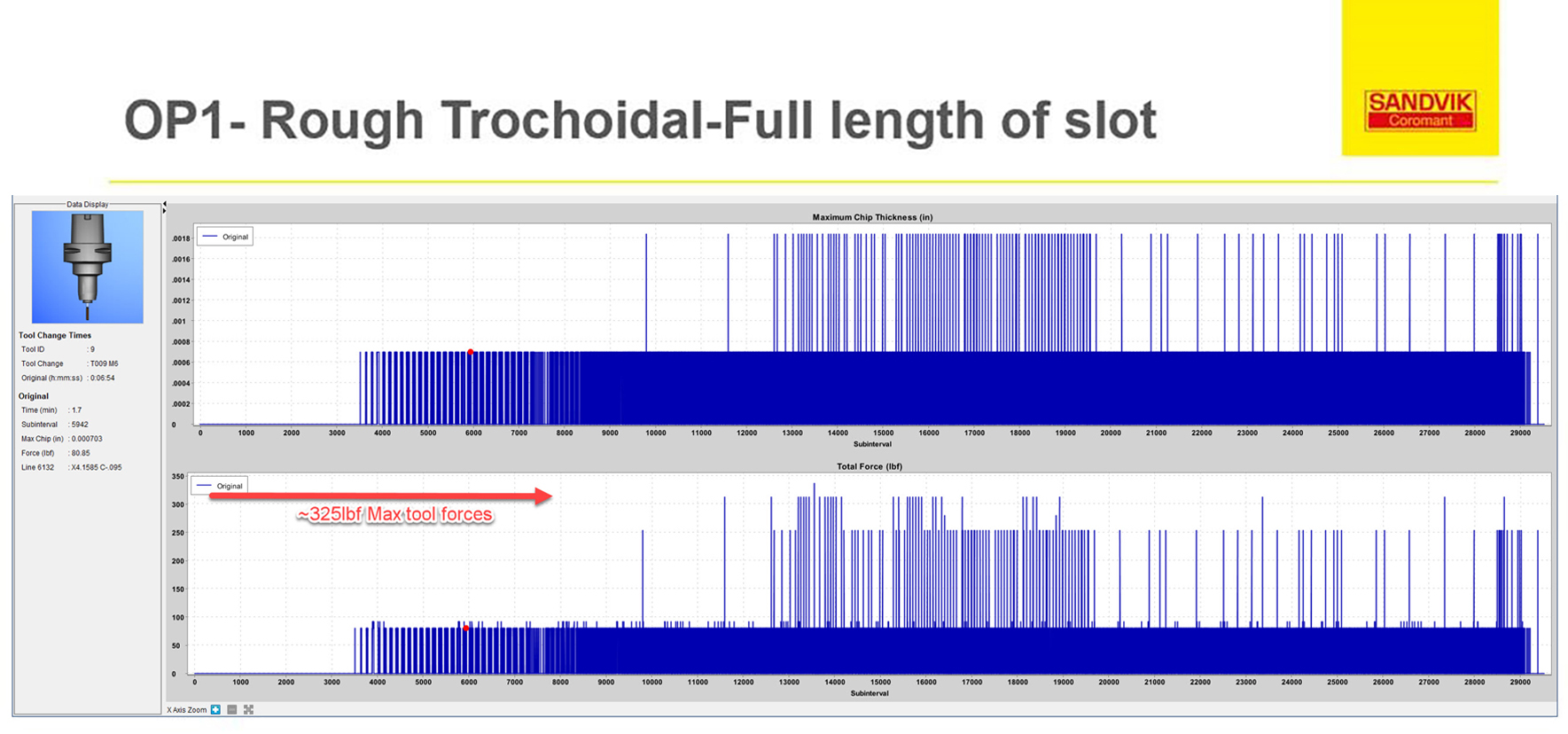

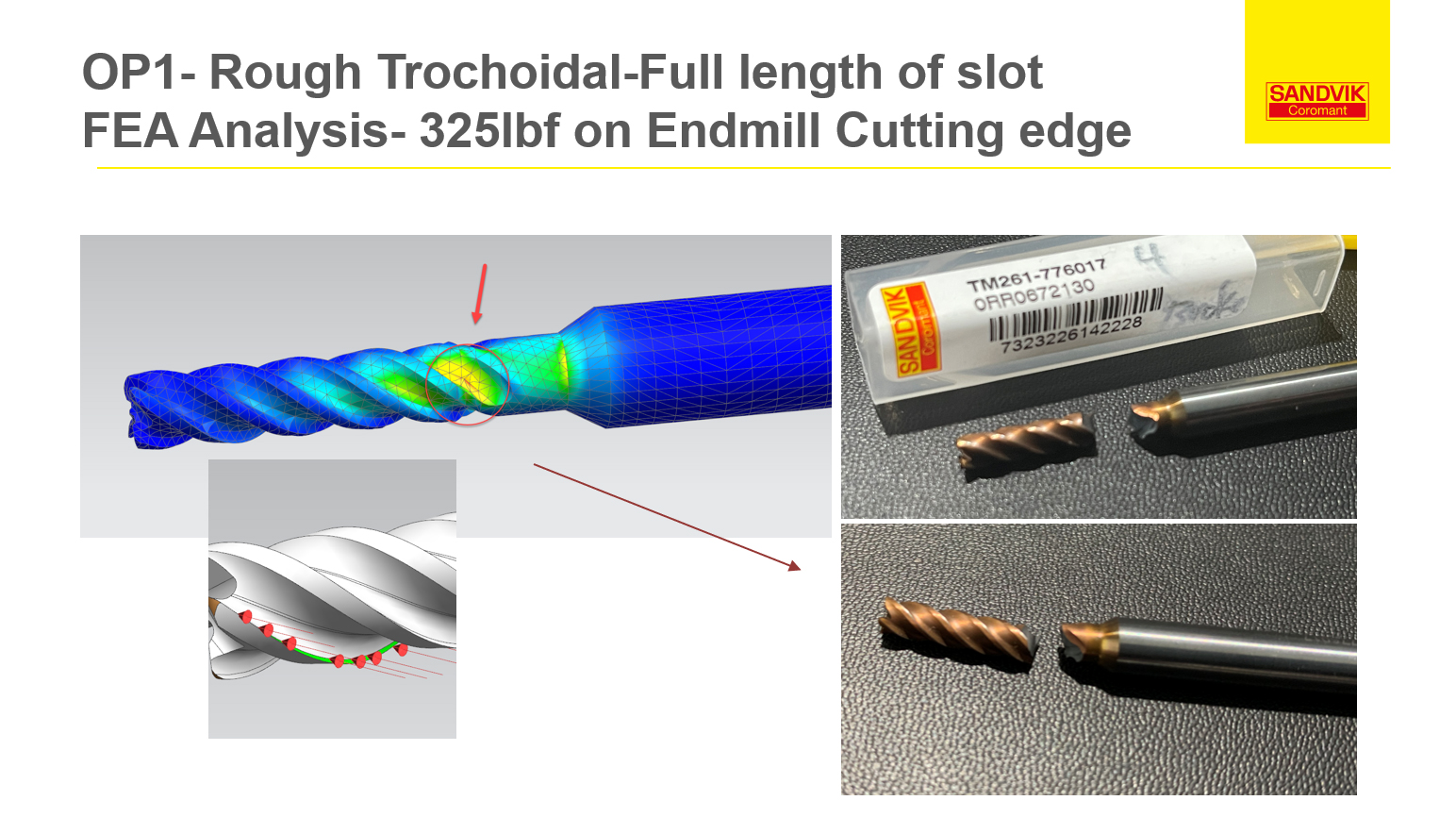

Using Force Analysis, which graphically analyzes the cutting conditions generated by an NC program, John was able to reveal areas of concern in the original program, including the cause of the repeated tool breakage. Force Analysis showed excessive forces of up to 325lb on the cutting tool- this proved to be the issue for the tool failure. John conducted a Finite Element Analysis (FEA), and the results showed that when the max total force was applied to the cutting edge of the endmill, the failure area on the endmill correlated with the maximum stress point on the endmill on the FEA graph (see image below).

Force Analysis allows users to investigate and understand problem areas within the NC program. Force Optimization takes it one step further, by automatically making the necessary revisions to the original program. The alternative is to make manual revisions to the program in the CAM software, sometimes requiring multiple iterations to resolve issues.

John Giraldo says, “I was shocked by how much value that analyzing the charts and data can tell about an operation. By looking at the readings of the total forces on the cutting tool I was able to start determining if the operation will cause the tool to fail or succeed during the machining process. This was a breakthrough in the project as I was able to modify my toolpaths inside the CAM software and analyze them before starting any machining process. The analytics offered in VERICUT Force tell the story of a cutting tool from start to finish and give you the power to change the outcome of the story. It definitely saved us a lot of time and cutting tools on this project.”

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan