In the automotive industry, managing high volumes and establishing efficiencies is key. As consumer vehicles shift from traditional internal combustion engines to hybrid and new electric vehicles, there's a lot of re-tooling and new tooling of components. VERICUT makes it easy to simulate the machining process to increase output and reduce costs with proper production planning.

Explore Resources and User Stories

-

MERCEDES-AMG PETRONAS FORMULA ONE TEAM User Story

Learn how VERICUT provides safe and optimized machining operations for the MERCEDES-AMG PETRONAS FORMULA ONE TEAM

-

Keselowski Advanced Manufacturing User Story

Keselowski Advanced Manufacturing specializes in the design and production of 3D-printed metal parts that are finished-machined on high-end CNC machine tools. One mistake can undo weeks of work and cost tens of thousands of dollars in material and machine time.

Learn why Keselowski Advanced Manufacturing uses VERICUT when machining parts that cost a small fortune.

-

EXCO Engineering User Story

EXCO Engineering uses VERICUT to visualize, modify, and verify their NC program before machining their automotive dies. Read more about how they skipped the prove-out process without tool breakage, collisions, or long run times.

-

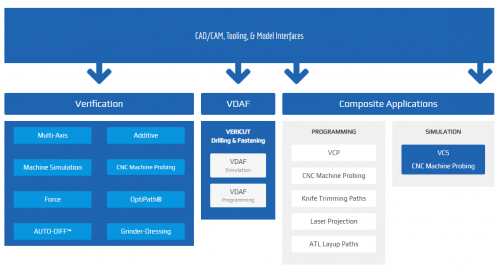

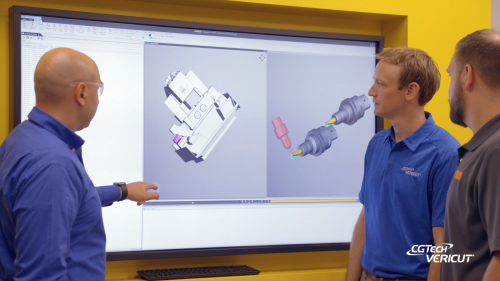

Explore Our Full Product Line

VERICUT offers solutions in machine simulation, verification, optimization, and more. Find the right modules to protect your CNC machines while increasing throughput.

-

VERICUT Force Optimization

VERICUT Force Optimization optimizes new and existing NC programs according to changes in cutting conditions. Protect your CNC machines and extend your tool life; watch the user story from Sandvik Coromant Mebane.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan